Zhangjiagang Kiwex Machinery Co.,Ltd

The PVC pipe extrusion machine is used to produce pipes with different diameters by replacing extrusion dies. It can produce every size of pipe in the area of the agricultural water supply system, architectural water supply system, pavement of cables, etc. It can produce the conduit pipe, pressure pipe, water pipe, drainage pipe, etc.

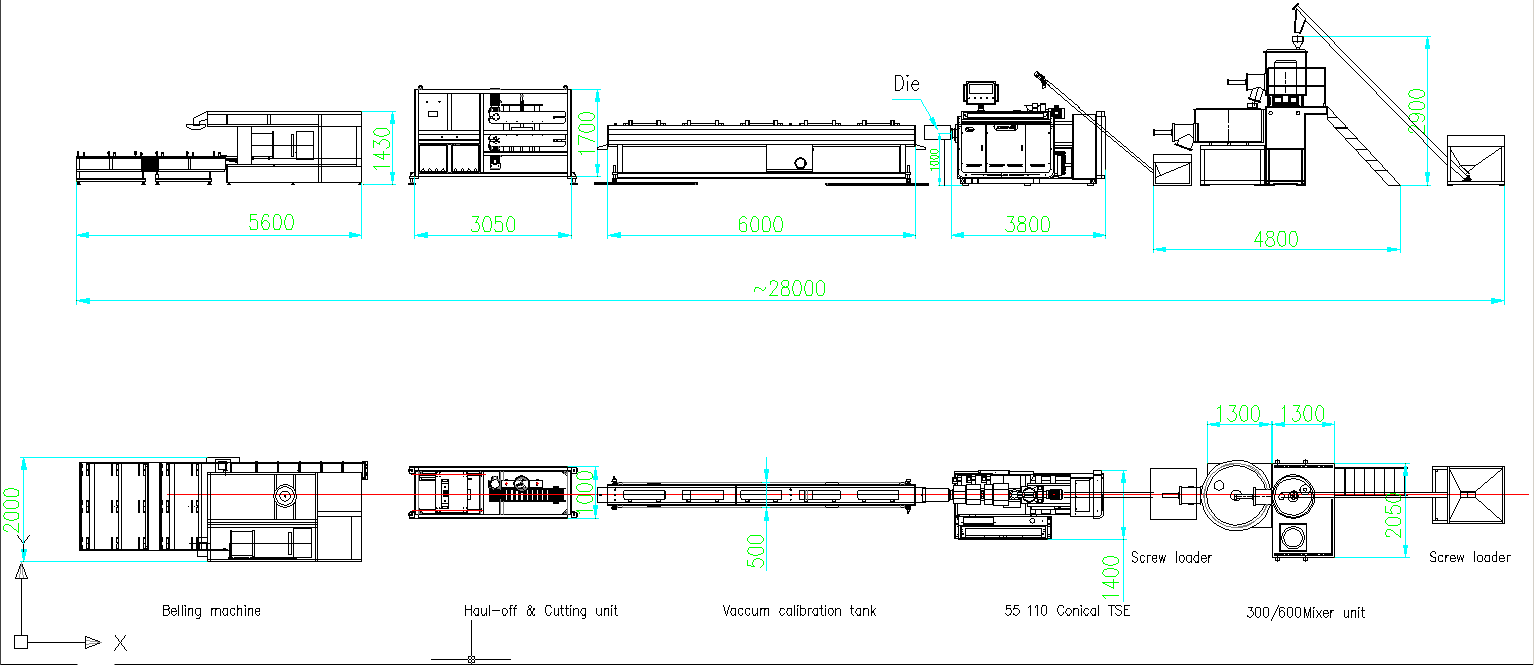

The PVC pipe extrusion machine is actually a series of main machines with optional auxiliary machines. (Pls refer to the table below. )So we also call it the PVC pipe extrusion machine line.

1. Conical double screw extruder adopts 38CrMoAlA material screw and barrel, nitriding process. It is a special design for PVC powder extrusion. By changing the die and auxiliary machines, it can produce many products like PVC profile, PVC ceiling, PVC trunk, PVC door, PVC foam board, etc.

2. PVC pipe extrusion die is made of 40Cr, which is used to modify and shape the final products.

3. The vacuum calibration tank body is made of stainless steel. The tank is equipped with a vacuum pump and a water pump. It is used to cool and size the pipe with a vacuum environment. It works together with pipe die parts sizing sleeve to make the PVC pipe into wanted diameter and into a round shape. It can also a little adjust pipe thickness. Its cover material is cast-aluminum.

4.The haul-off machine has many models to choose from according to pipe OD like 2-claws, 3-claws, 4-claws, 6-claws, 8-claws, 10-claws, etc. This part is used to haul the pipe at the same speed as the extrusion. Sometimes it can have the function to adjust PVC pipe thickness a little. When its speed is higher than extruder, the pipe wall becomes thinner while its speed is lower than extruder, pipe wall becomes thicker. Hauling speed is controlled by ABB inverter.

5.The planetary cutter of the PVC pipe production line is used to cut pipes into wanted length such as 3m, 3.5m length, etc. It is controlled by PLC. (Want to know how to operate cutter, click planetary cutter)

6.Stacker is made of stainless steel. It is used to place the pipe products after cutting.

How is PVC pipe extruded?

1.Mix raw material by mixing machine: PVC powder + additive→

2.load mixed material to feeder by screw loader →

3.Melt mixed material through a conical screw (designed for PVC powder especially) →

4.Extrude melted material into rough pipe shape by extrusion die →

4.cool and blow pipe to shape it better by water and vacuum in vacuum cooling machine →

5.haul off the pipe with the same speed of extrusion to control production speed and pipe thickness→

6.cut pipe into customized length by a cutter→

7.place and discharge pipe(controlled by a limited switch) by stacker automatically.

Investment:

It is another important factor you need consideration. You must be interested in what total capital is required to start a PVC pipe plant. Now let us tell you.

You should make sure you have at least 150,000$ as start-up capital so you can buy a small PVC pipe making machine and buy material to produce for one week first. But the cost of the workshop fee is not included. The final cost depends on the actual situation. We, Kiwex Machinery, can help you to count the cost and profit according to customers’ specific requirements.

After the purchase of the machine, we will supply material formula and material purchase suggestions.

About the machine, we can recommend a machine according to your budget and your requirements.

Regarding technical support, we will supply operation instructions, video guides, and online support. And we can supply field installation, commissioning and worker training.

Before the sale, we supply the quotation, pictures, videos of the machine and the count of cost &profit as well as suggestions on factory area and quantity of employees.

After sale, we supply the testing machine free of charge, a 13months quality guarantee of spare parts and 24-hour technical support.

Conclusion

After reading the article, you must have known about PVC pipe extrusion machine and how to start a pipe plant. If there is still something not clear, or you want more information about the plastic pipe manufacturing machine. Welcome to leave a comment or contact us directly. And welcome to visit our factory Kiwex Machinery in Zhangjiagang city. We would give you a warm welcome.